In any hydraulic system, valves play a vital role in controlling pressure and maintaining system safety. Two commonly misunderstood components are the hydraulic pressure relief valve and the hydraulic pressure reducing valve. While they both regulate pressure, their purposes, functions, and applications differ significantly. In this article, we’ll break down the core differences and help you understand when to use each one.

Hydraulic Pressure Relief Valve vs Hydraulic Pressure Reducing Valve: What’s the Difference?

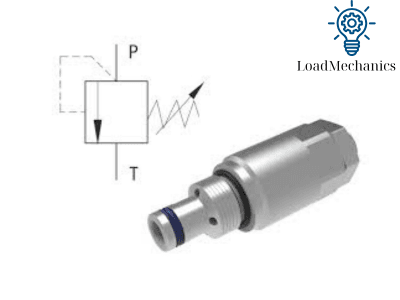

1. What Is a Hydraulic Pressure Relief Valve?

A hydraulic pressure relief valve is a critical component in hydraulic systems that helps maintain safety and prevent damage by controlling fluid pressure. When the pressure in a hydraulic system exceeds a certain limit, the relief valve opens to divert the fluid, preventing overpressure situations. This simple yet crucial device plays a significant role in safeguarding machinery and preventing catastrophic failures.

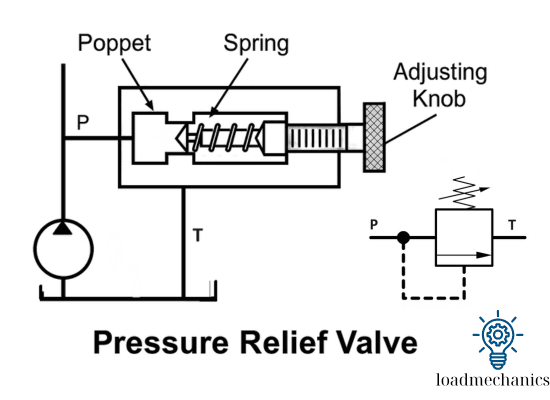

How Does a Hydraulic Pressure Relief Valve Work?

Hydraulic pressure relief valves are designed to open and allow fluid to flow back to the reservoir when the system pressure exceeds a preset limit. This action ensures that the pressure does not reach dangerous levels, which could damage system components such as hoses, seals, pumps, or actuators.

Normal Operation of a Pressure Relief Valve:

📌 When system pressure is below the set value:

Hydraulic fluid flows from the pump to the system through port P (pressure).

The spring applies force on the poppet, keeping the valve in the closed position and preventing flow to the tank port (T).

At this stage, the valve remains closed.

📌 When system pressure exceeds the preset limit (due to overload, blockage, etc.):

System pressure acts on the poppet, overcoming the force of the spring.

The poppet is pushed open, allowing hydraulic fluid to flow from P to T.

This relieves excess pressure by diverting fluid back to the tank, protecting the hydraulic system.

📌 After pressure drops:

The spring force pushes the poppet back to its original position → the valve closes again.

Key Functions of a Hydraulic Pressure Relief Valve

- Pressure Control: The primary function of a hydraulic pressure relief valve is to control and limit the maximum pressure within the system.

- Protecting Equipment: By diverting fluid during overpressure situations, the valve prevents damage to critical components, ensuring the longevity of the system.

- Ensuring System Safety: Hydraulic systems can be dangerous if pressure builds up too high. The relief valve acts as a safety feature to reduce risks of accidents or failures.

- Maintaining Efficiency: By regulating pressure, the valve helps keep the system running smoothly and efficiently, ensuring consistent performance.

Applications of Hydraulic Pressure Relief Valves

Hydraulic pressure relief valves are used in various industries and applications, including:

- Manufacturing Equipment: To protect hydraulic presses and machines from damage due to excessive pressure.

- Construction Equipment: Such as excavators and loaders, where the valve helps maintain safe pressure levels in lifting operations.

- Agricultural Machinery: In tractors and harvesters, hydraulic relief valves ensure safe operation by controlling pressure in hydraulic systems.

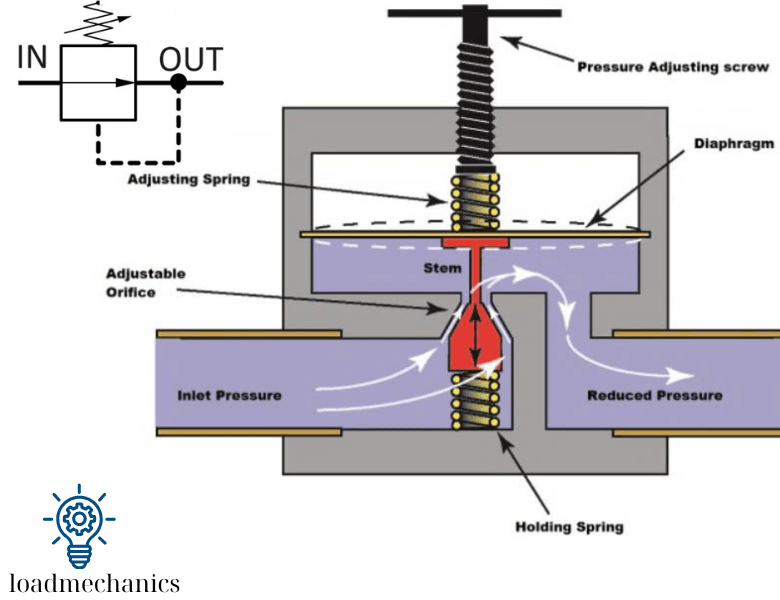

2. What Is a Hydraulic Pressure Reducing Valve?

A hydraulic pressure reducing valve is an essential component in hydraulic systems that ensures specific sections of the system operate at lower pressures than the main system. By regulating and reducing the pressure in a particular circuit, these valves prevent damage to sensitive equipment and ensure efficient performance. Unlike pressure relief valves, which protect the system from overpressure, pressure reducing valves are used to maintain a consistent, lower pressure for specific applications.

How Does a Hydraulic Pressure Reducing Valve Work?

A hydraulic pressure reducing valve functions by automatically adjusting and maintaining the pressure in a specific part of the system to a preset, lower level. When the pressure in a circuit exceeds the set value, the valve activates and allows fluid to bypass, reducing the pressure in the branch line while maintaining the higher pressure in the main hydraulic system.

📌During Normal Operation:

- Hydraulic fluid (or compressed air) enters the IN (Inlet Pressure) port.

- The adjusting spring applies force on the diaphragm, which pushes down the stem, keeping the adjustable orifice open.

- This allows fluid to flow from the inlet to the OUT (Reduced Pressure) side.

📌 When Downstream Pressure Increases (Above Set Value):

- The increased downstream pressure pushes up against the diaphragm.

- This causes the stem to lift, gradually closing the orifice.

- The reduced orifice opening limits flow, lowering the downstream pressure back to the desired setpoint.

📌 When Downstream Pressure Drops:

The spring force overcomes the reduced pressure beneath the diaphragm, pushing the diaphragm and stem downward.

- This opens the orifice wider, increasing flow and restoring pressure to the target level.

This means that while the main hydraulic system may be operating at a higher pressure for general tasks (like lifting or pushing), sensitive equipment or smaller actuators downstream are supplied with a lower, more controlled pressure. This feature is especially useful in systems where precision and safety are required.

Key Functions of a Hydraulic Pressure Reducing Valve

Maintaining Stable Pressure: The primary function of a pressure reducing valve is to regulate and stabilize the pressure in certain sections of the hydraulic system.

Protecting Sensitive Equipment: Certain components in the hydraulic system, such as actuators or precision tools, require a lower and more consistent pressure to function properly.

Preventing Overpressure in Subsystems: The valve prevents the downstream circuits from exceeding pressure limits, which could lead to equipment failure or poor performance.

Optimizing System Efficiency: By ensuring consistent pressure in branches, the reducing valve helps the system function at its optimal efficiency.

Applications of Hydraulic Pressure Reducing Valves

Hydraulic pressure reducing valves are commonly used in various industries to ensure that components in different parts of the system receive the appropriate pressure:

Mobile Equipment: In systems requiring precise control for actuators or motors, reducing valves are crucial to maintain proper operation without damaging components.

Manufacturing: In automated machines and presses where different pressures are required for different stages of production.

Construction Equipment: Hydraulic pressure reducing valves are used in machines like excavators and cranes to control pressure in different subsystems (e.g., lifting arms, rotating sections).

Agricultural Machinery: Tractors and harvesters benefit from these valves to protect sensitive hydraulic components from excessive pressure.

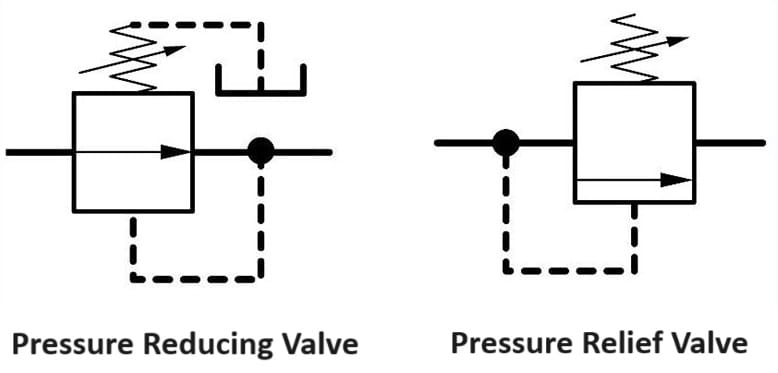

3. Key Differences Between Pressure Relief and Reducing Valves

| Aspect | Pressure Relief Valve | Pressure Reducing Valve |

|---|

| 1. Function and Purpose | Protects system by releasing fluid when pressure exceeds a preset limit (safety function). | Maintains constant downstream pressure regardless of upstream fluctuations (control function). |

| 2. Working Principle | Opens only when system pressure exceeds setpoint to release excess pressure. | Stays slightly open and adjusts based on downstream pressure to regulate it. |

| 3. Installation Location | Installed near the pump or pressure source on the pressure line. | Installed downstream to regulate pressure to specific parts of the system. |

| 4. Response Behavior | Reacts only in overpressure situations. | Continuously responds to pressure changes during normal operation. |

| 5. Purpose in System | Ensures system safety and prevents damage. | Improves efficiency and protects downstream components via controlled pressure. |

4. When to Use Each Valve

🔺 Pressure Relief Valve

- ✅ Use it when system protection is a priority.

- Installed near the pump or high-pressure source to prevent overpressure, which could damage components or cause system failure.

- Ideal for hydraulic power units, mobile machinery, and industrial presses where pressure spikes can occur.

🔻 Pressure Reducing Valve

- ✅ Use it when controlled and stable downstream pressure is needed.

- Installed downstream to regulate pressure for sensitive equipment, actuators, or sub-circuits that require lower or constant pressure.

- Common in robotics, CNC machines, pneumatic tools, and multi-zone hydraulic systems.

🧩 Summary Tip:

“Use a relief valve to protect. Use a reducing valve to control.”